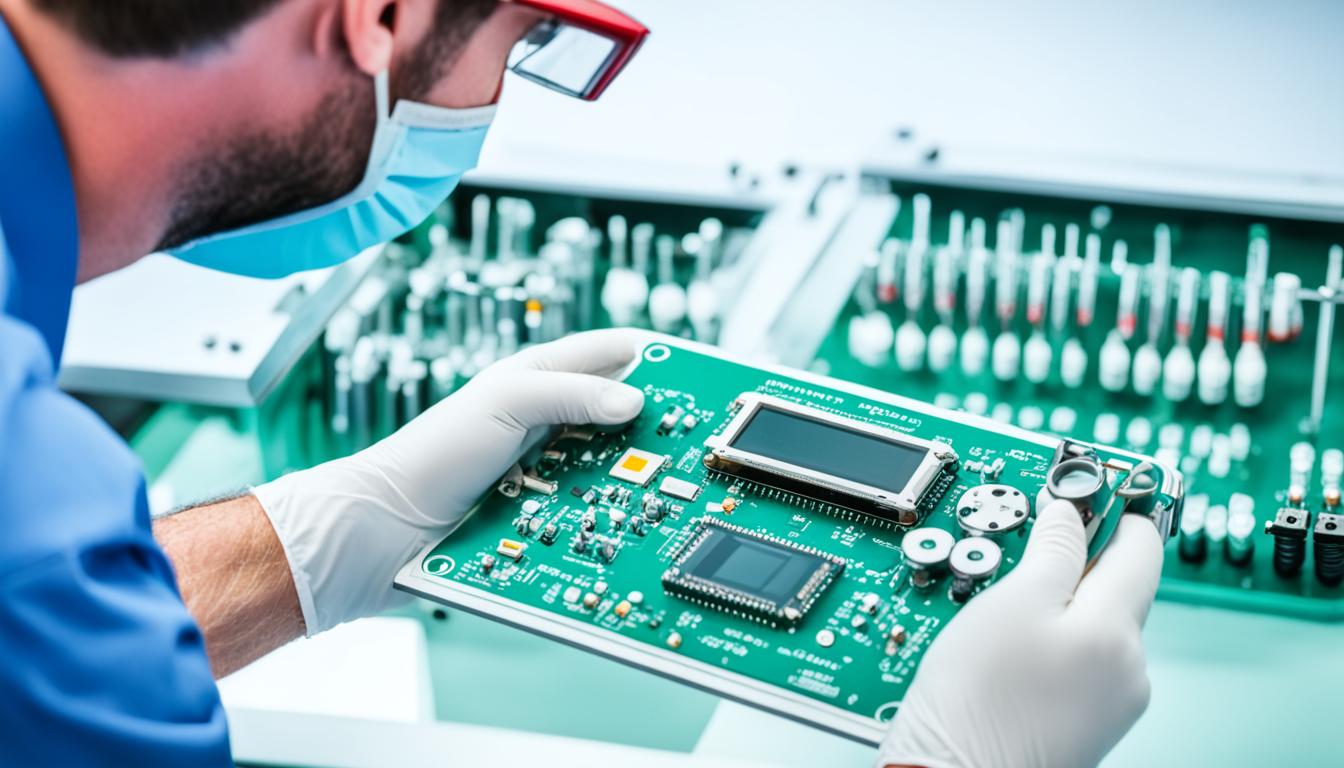

In the fast-changing world of medical tech, patient safety is key. THY Precision ISO standards for medical devices are very important. But what does ISO 13485 really mean and how does it affect us? For healthcare workers or those in the industry, knowing about this standard is key. It helps with following the rules, lowering risks, and giving top-quality medical products to patients.

Key Takeaways

- ISO 13485 is the globally recognized standard for quality management systems in the medical device industry

- Compliance with ISO 13485 is often a prerequisite for regulatory approvals, making it a vital component of the medical device supply chain

- The standard ensures meticulous monitoring at every stage of the manufacturing process, guaranteeing the safety, conformity, and excellence of medical devices

- By adhering to ISO 13485, organizations can reduce risks, foster innovation, and reinforce trust in medical technology, ultimately safeguarding public health

- Understanding the meaning and importance of ISO 13485 is crucial for healthcare professionals and industry stakeholders

What is ISO 13485 and its Importance for the Medical Device Industry

The healthcare sector is always changing, and so are the rules for medical devices. ISO 13485 is a key standard for companies making and selling iso standards for medical devices. It helps them follow quality management rules.

Unpacking the ISO 13485 Standard

ISO 13485 is a detailed guide for medical device companies. It helps them make sure their products and services meet customer needs and laws. It covers everything from design to making sure devices are safe and traceable.

The Significance of ISO 13485 in Regulatory Compliance

The “Requirements for regulatory purposes” in the title show how important iso 13485 meaning is. It helps companies follow complex laws in the medical device field. Being compliant with this standard is often needed to sell products in many countries.

“Compliance with ISO 13485 serves as a market entry ticket in many countries, making it virtually indispensable for navigating the complex regulatory landscape of the medical device industry.”

Using a strong iso 13485 meaning quality management system helps companies. It makes products safer and more effective. It also makes the company more efficient and builds trust with customers. This is key to doing well in a strict industry.

Key components of ISO 13485

At the core of ISO standards for medical devices and the ISO 13485 meaning is a strong Quality Management System (QMS). This system has the needed steps, processes, and tools. It helps companies like THY Precision meet their quality goals for their products and services. Quality Assurance is key, focusing on checks, inspections, and tests to make sure products and services meet the needed standards.

Quality Control is also vital, focusing on stopping defects in the final product or service. Quality Improvement works to make products and services better, aiming to go beyond what customers and rules expect. These parts together make the QMS strong, helping companies manage their quality goals well.

| Key Component | Description |

|---|---|

| Quality Management System (QMS) | Provides the needed steps, processes, and tools to help companies meet their quality goals. |

| Quality Assurance | Includes checks, inspections, and tests to make sure products and services meet the needed standards. |

| Quality Control | Focuses on stopping defects in the final product or service through checks. |

| Quality Improvement | Works to make products and services better, aiming to go beyond what customers and rules expect. |

These parts work together to make the quality management system of companies like THY Precision strong. They help them always deliver top-quality medical devices that meet the industry’s strict rules.

Implementing ISO 13485:A Strategic Approach

As a leading medical device maker, THY Precision knows how vital it is to follow iso standards for medical devices and the iso 13485 meaning. They use a strategic plan to put ISO 13485 into action. This starts with a detailed gap analysis and readiness assessment. These steps help see where they stand now and what steps to take to meet the standard.

Gap Analysis and Readiness Assessment

The gap analysis helps THY Precision see how its quality management system stacks up against ISO 13485. This deep dive shows what’s missing and what needs work. With this info, THY Precision can make a plan to smoothly adopt iso 13485 meaning.

Steps for Successful Implementation

Putting ISO 13485 into action at THY Precision means following a clear process. It starts with making policies and documents that meet the ISO 13485 rules. Then, training employees is key to teach them about the standard and its benefits.

Next, it’s time to put the plan into action. A flexible SaaS platform helps automate tasks and keep track of data. Regular checks and reviews make sure the quality system stays strong and up to date, leading to ongoing improvement.

Benefits of Implementing ISO 13485

Getting iso 13485 meaning right brings big wins for THY Precision. It boosts their quality management system, making things more transparent and data-driven. This helps them meet strict medical device industry rules, showing they care about patient safety and following the law. ISO 13485 also helps the company grow, letting them innovate and stay ahead in the global market.

iso standards for medical devices,iso 13485 meaning

As a medical device maker, THY Precision knows how vital iso standards for medical devices and the iso 13485 meaning are. They ensure quality, safety, and follow the rules. ISO 13485 is the top standard for quality in the medical device field. It helps make sure devices are safe and work well.

The iso 13485 meaning is all about putting patients first and following the rules. It’s about regulatory compliance and risk management. This standard gives companies the tools to lower risks and make products that are top-notch in quality and safety. By following iso standards for medical devices, THY Precision shows it cares about patient safety and builds trust with everyone involved.

Choosing to follow iso 13485 meaning puts THY Precision ahead in the global market. This standard helps the company meet rules and get better at what it does. It also helps bring new ideas to life and make products that meet the changing needs of the medical field.

“Implementing iso standards for medical devices is not just a compliance exercise; it’s a commitment to patient safety and a testament to our dedication to excellence.”

– THY Precision leadership team

At THY Precision, we stick to the iso 13485 meaning and use iso standards for medical devices to make sure our devices are always top quality. This focus on quality and following the rules is key to our success. It’s what we rely on to make strong bonds with our customers and partners in the industry.

Risk Management under ISO 13485

At THY Precision, we know that ISO standards for medical devices and the ISO 13485 meaning are key for keeping patients safe and following the rules. The standard has a strong risk management plan. Let’s look closer at how ISO 13485 handles risk management.

The ISO 13485 standard says companies must use a systematic, risk-based method for all stages of a medical device’s life. This includes four main steps:

- Risk Identification: Finding potential dangers that could affect your medical devices’ safety, performance, or quality.

- Risk Evaluation: Figuring out if the risks are okay, based on how likely and severe they are.

- Risk Control: Taking steps to lower risks to a level that’s as low as reasonably possible (ALARP), making sure your products are safe and work well.

- Risk Monitoring: Keeping an eye on how well risk control steps work and changing them if needed.

By using this structured risk management method in all parts of your work, THY Precision can make sure your medical devices are safe and work right. This builds trust with your customers and the people who make the rules.

“Effective risk management is the key to making high-quality, safe medical devices that meet or beat the rules.”

Following the ISO 13485 and its detailed risk management plan is very important for companies like THY Precision. By actively finding, checking, controlling, and watching risks, we put patient safety first. This helps us deal with the tough rules with confidence.

Conclusion

The iso standards for medical devices and the key iso 13485 meaning are vital for quality in the medical device field. They help companies like THY Precision show they care about patient safety and follow the rules. This also opens doors for growth and new ideas.

These standards focus on managing risks, controlling designs, and checking processes. This lets THY Precision move through tough rules with ease. It brings more openness, uses data for better decisions, and keeps improving. Following iso 13485 meaning is crucial for any company wanting to stand out in the competitive medical device world. It helps them move healthcare technology forward.

The role of iso standards for medical devices and iso 13485 meaning will keep getting more important. By using a strong quality system based on these standards, THY Precision and others can make sure their devices are safe and work well. This leads to better patient care and pushes the industry ahead.